PRODUCT Description

Waterproofing cement compound, of two components (powder A, liquid B), forms a complete waterproofing system after mixing, to prevent water leaks for internal and external applications.

- Internal and external insulation for old and modern buildings.

- Water insulation for tunnels, irrigation, canals, and dams.

- Insulation for small and huge Betonwater tanks, drinking water tanks, and swimming pools.

- Isolate retaining walls and building foundations.

- Insulation for inspection chambers in sanitation and seaports.

- Water-submerged basements and coveredchannels.

- Full isolation system for negative and positive pressure.

- Suitable for application in drinking water tanks for lack of toxic chemicals or smell when applied.

- High flexibility and excellent performance.

- Perfect adhesion and homogeneity with the surfaces applied to them.

- Good resistance to saltwater, sulfur and air pollution.

- Freeze-resistant.

- Protects concrete and reinforcement exposed to water from the effects of chloride and phosphate.

- Easy to prepare and ready to apply.

- Can be used as a final layer without coating.

- In the case of wet surfaces, it is used directly, but on surfaces exposed to negative pressure and flowing water, a quick-hardening cement must be used, and then AkreHydrocut 2075 is applied.

- Crack-resistant, even on uneven surfaces.

1- Preparation of substrate :

- The surface must be structurally sound, clean and free from oil, dust, paint and other residues.

- Wetting the surface well, before application, making sure that it is free from any pools of stagnant water.

- If there are holes in the surface (screw and nail holes) it must be dry and free of water.

2- Application

- Mixing:

The liquid component is placed in a clean bowl and then the powder is on top of it (and not vice versa) in a ratio of mixing 20 kg of powder to 5 kg of liquid, then mix constantly using a mechanical low-speed mixer (3-6 minutes) until we reach a homogeneous mixture free of clusters, in a form of paste.

- Spreading :

AKRE HYDROCUT 2075 is applied in two layers in the same direction using a trowel so that we apply the second layer when the first layer is at the beginning of its hardening (still soft), i.e. 3-4 hours after applying the first layer according to the existing ventilation. The mixture should be used within 20 minutes after mixing . The consumption is :( 1.9 kg / m2 ) .

Post-application recommendation:

- The isolated area should be moistened and watered 24 hours after applicationfor 7 days.

- Tanks, dams, and lakes that are isolated with AKRE HYDROCUT 2075, fill after the substance is dry for a period ranging from 3-5 days.

- - Do not apply AKRE HYDROCUT 2075 at temperatures below 5°C.

- - Evaporation arrester systems are not suitable for use in the AKRE HYDROCUT 2075 system.

Cleaning: :

- Clean equipment and hands with direct water

- Clean the surface of the stuck material after installation with a wet cloth.

Storage:

- - Storage in relatively dry warehouses away from humidity and direct sunlight.

- - shelf life 12 months in appropriate conditions.

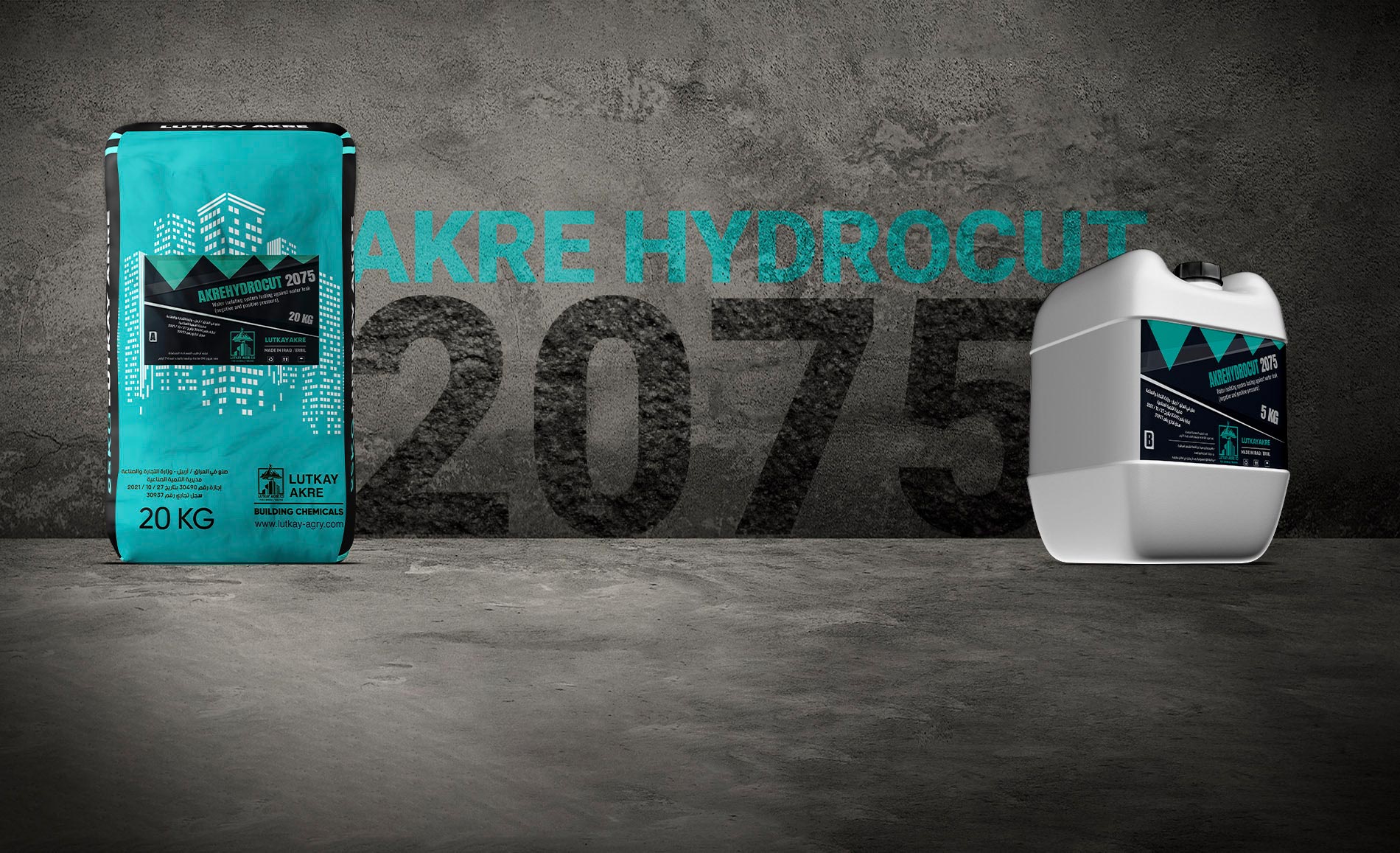

Packaging:

- Powder component A : Multi-ply paper bag 20 kg.

- Liquid component B : Plastic Gallon 5 kg.

Safety recommendations:

AKRE HYDROCUT 2075is a chemical compound containing substances that cause eye irritation and skin sensitivity so the following safety instructions must be adhered to:

- Wear gloves and goggles while working.

- Wear masks to protect respiratory health.

- Any scratch on the skin or eyes should be treated with pure water immediately.

- If the substance is ingested by mistake, a doctor must be checked immediately without attempting to stimulate vomiting.

|

Technical Properties |

|

| Appearance | powder |

| Color | Powder A: White - Liquid B: White |

| Density | 1.9 g/cm3 |

| Pressure stress after 28 days | 35 Mpa |

| Tensile stress | 3.3 Mpa |

| Flexibility factor | 2.9 Gpa |

| Adhesion stress | 1.66 Mpa |

| Resistance on negative pressure | 20 bar. |

| Abrasion resistance (new concrete equation) | 72 |

| Expansion of sample in hard environment | No expansion 0% |

| Effect of see water ( after 90 days in high salt concentrated solution) | No effect 0.0275% |

| Sulfur salts (after 90 days in high sulfuric salt concentrated solution) | Good resistance on long-term 0.413 |

| Water leakage inside AKRE HYDROCUT 1075 under the pressure of 8.4 bar continuously for 24 hours | 0mm |

| Resistant to solvents and alcohols | High (as per ASTM 543) |

| Resistance to oils | High (as per ASTM 543) |